From the past few years, many changes are already existing nowadays, like the way products get stored and warehouse operations. The new technology that is associated with building storage systems has enhanced considerably in the last several years. You can now find custom mezzanines and types of storage options that are better designed not just to improve space utilization but furthermore efficiency.

The mezzanine floor often projects itself from the walls and does not completely close the view of the ceiling from the floor immediately below. In short, a mezzanine floor and the floor below it share the same ceiling. Mezzanine floors are often located between the ground floor and the floor above, but it is not unusual to have mezzanine floors in the upper floors of a building.

Many pre-engineered steel mezzanines and work platforms make it easy and useful to integrate a single or multi-level platform into your valuable project, without the disruption of construction. Many manufacturers were worked within your footprint to create an affordable solution that will improve your overall workflow.

Yes, these mezzanine systems can be a less expensive method to create the best usage of available building space. It is ordinarily a structure that is made including the main floor to constantly help additional supplies or equipment. These systems are very cost effective you may need to the productive operation of your industrial business and because of being moveable, they can be relocated anywhere on your existing warehouse space.

The mezzanine storage method is best found in conditions where there’s very little product to warehouse. In the massive operation, this would not be the optimum method of employ. However, the cost is leaner in comparison to other people.

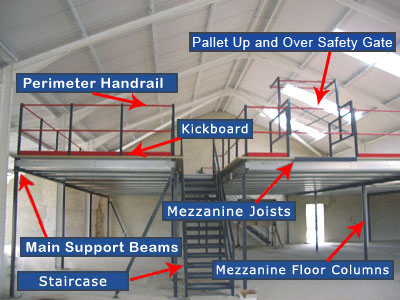

If you have an existing space in your warehouse and you cannot handle it or solve it by yourself, Material Storage Systems can drastically ease your worries away. We can offer lots of custom mezzanines that can help you accommodate unusually high structures, very long spans as well as any movement considerations. We can also customize stairs, ladders, cross-overs, gates and floorings for your next mezzanine project.

To contact us, you can determine your concerns by dialing (800) 881-6750 or you may e-mail us at sales@msshouston.com to have an immediate response from one of our experts.